The Briiv Story (So Far!)

We’re all so proud here at Briiv of how far we’ve come over the past few years that we decided to take a look back at how the world’s most sustainable air purifier came to be.

The idea for Briiv began in 2019. After spending years designing products for other companies, the Briiv designers James and Sean wanted to put their heads together to come up with their own product that could both improve health and support the environment. As a small company, the heads at Briiv knew that they couldn’t jump right in with industry changing concepts and needed to start small. Researching various avenues that focused on their sustainable ideals, air purification was identified as an area with potential. As a pretty niche industry at the time, the processes across other brands were fairly consistent, which led to plenty of room for innovation. Generally plastic heavy, and producing long-term pollutants in the form of disposable filters, sustainability wasn’t anywhere near the air purifiers on the market, and the team behind Briiv wanted to change that.

Sustainability has always been at the heart of everything Briiv does, and with this as a starting point we began looking at ways current air purification systems could be modified to make products which are better for people and the planet. There was a LOT of trial and error in the early days, with the first ever Briiv prototype being made from an industrial coffee tin and acrylic tubing! Looking into various natural fibres as filtration components and seeing what worked well together involved plenty of experimentation. When James saw an article about a solar powered car which had moss built into the dashboard to act as a filter, he was inspired. There were various attempts to keep moss alive whilst consistently drawing air through it, or using wool to filter particulates out of the air, until eventually, 37 variations later, we have the Briiv we all know and love today.

We knew that developing Briiv would require funding that we couldn’t provide ourselves, so we considered different ways we could raise the money to develop Briiv and get it ready for production. This ultimately led us to crowdfunding through Kickstarter, and following success there Indiegogo as well. Ryan, the third prong of Briiv, had extensive experience with crowdfunding and fulfilment. The Kickstarter campaign launched in April 2020, and just a month later we were fully funded! By June 2020 the campaign was over, and 658 backers pledged over triple our goal. As we continued to gain support through Kickstarter even past our goal, we were able to explore new options for Briiv that had previously been mere ideas for future iterations. Now we could explore in earnest different filter options, as well as develop the touch free user interface that all Briiv units now have. This felt especially pertinent with the increasing rise of COVID cases and the concerns around high touch points and contamination.

In July 2020, just over a year after the idea for Briiv began, we had the funds to begin production. Working with developers, Vibers (who created the bioplastic we use for Briiv), and manufacturers we wanted to get the first wave of Briivs produced and assembled in our little Leeds workshop as soon as possible. Unfortunately, due to COVID travel restrictions we were unable to do in-person quality checks as we’d have liked, meaning not quite everything was up to scratch. This was really disheartening at the time as it was out of our control and pushed our production timeline way back. While initial fulfilment was planned for Februrary 2021, we had to delay this by a month to account for the extra round of production.

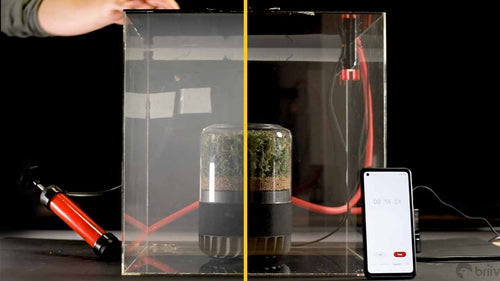

On the bright side, this period of waiting meant we had more time to look into future developments to improve Briiv in the long run. This led to us developing the nano-matrix filter for Briiv, which performed significantly better than the original wool filter. We decided to switch tracks and put the extra time we had into producing the matrix filters for all of the units in our initial run. The performance improvements basically made the choice for us- after all, cleaner air for all is why we made Briiv in the first place!

As we got closer to our planned fulfilment date, the pandemic was still having massive effects on individuals and businesses worldwide. In January 2021, just two months before we wanted to begin fulfilling pledges, we hit a huge roadblock. Due to panic-buying within the sector, microchip shortages meant orders we’d placed for the Briiv electronic components couldn’t be fulfilled. This meant the electronic component of Briiv had to be redesigned to work with what was available, and unfortunately once again pushed our expected fulfilment date by another month.

While we waited for the correct components, we were able to develop Briiv’s recyclable packaging using cardboard and shaped pulp. This would ensure Briiv stayed safe during shipment without the use of bubble wrap or plastic. We also further developed the matrix filter and incorporated the previously separate activated carbon. This saved space and further reduced the waste created at the end of use.

In March 2021 we were lucky enough to be awarded the Red Dot Design award for designing ‘an innovative filter system that is visually attractive and makes an important contribution to environmental protection.’ Despite other set-backs at the time, we were incredibly proud of such an achievement. It gave the whole team a much needed boost, and a reminder that even during such a difficult time we were on track for making our ideas a reality.

In April, when we were hoping to begin our (already delayed!) fulfilment, but the global shortage of microchip and electronic parts impacted us even further as our supplier handed us another delay, this time with the WiFi modules which allow Briiv to connect to the app. At this point the delays felt out of hand and full of excuses, so instead of adding further to the delays we set to work fixing the problem ourselves. We were able to purchase different chips for the electronics boards that would go into Briiv, rather than having them pre-built, that we attached one by one in our Leeds workshop. This didn’t interfere with the use of the Briiv, but it did bring the time line under our control rather than at the mercy of suppliers!

At the time, this was a huge undertaking for our small team. We actually ended up bringing on more team members to help us build Briiv and keep up with our newest timeline. Altering the build process was a massive task with significant time and financial cost, but we simply didn’t want to delay any further! Sustainability isn’t just about the environment, it also means accessibility to parts so we can continue to make Briiv. We also need to be able to scale up to make Briiv available to as many people as possible, and we can’t do that if we don’t have the parts!

With the issue resolved, we could get stuck into building properly. At this point we only had our initial stock of bioplastic bases, but with the rest on the way we finally felt that we were getting back on top of things. We were able to start shipping out completed units, and were finally fulfilling the campaigns. Of course with the track record of production so far, we shouldn’t have gotten our hopes up. In the next month we received the second half of our bio-bases, and we were so excited to get the rest of the Briivs built! And then we opened the boxes…

It's not an exaggeration to say we were gutted. A lot of the bases were quite frankly a mess. There were boxes that had gotten wet during transport that had been stagnant for so long there was mold growing, and others had been exposed to extreme temperatures that warped the shapes and made them unusable. It was overwhelming, but we knew we had to figure it out. We were able to sort through which parts of the shipment hadn’t been affected, and we filtered through each of the warped bases to see if any were salvageable. After the microchip fiasco we now had to add even more late nights dedicated to reshaping the filter housing, but we knew we needed to do what we could to prevent waste, and at this point our backers had already waited so long that waiting for a completely new shipment just wasn’t feasible.

It wasn’t all doom and gloom though! During this time we also won the A’ design award for Briiv, and we brought on more staff to help us begin shipping the units that were ready to go. We were slowly but surely able to fix, build, and send out more and more units, until November hit and we could officially launch the Briiv store and make clean air accessible to even more folk! As we still had campaign pledges to fulfil, the store had a 12 week lead time. This gave us enough time to keep building and shipping, until by January 2022 we had fulfilled all of the Kickstarter pledges and had shipped Briiv out to 49 different countries! Over the next few months we could process store orders as well, and we finished Indiegogo fulfilment as well.

After the rocky start to the life, Briiv was finally providing clean air to homes and offices around the world. The rest of 2022 came in fast, with wholesale relationships growing along with our team, building up our customer base and working in the background to keep everything ticking over. Throughout June we were consistently working on app bug fixes and releasing patches while investigating why they were reoccurring. We even hired an in-house electromechanical engineer who could dedicate his time to this!

Towards the end of the year we moved out of our office and into a new warehouse space as we continued to grow, and we were building and shipping faster than ever; so fast in fact that we sold out way ahead of our projections! We had to introduce a lead-time to the webstore again while we waited for more stock, but the team all had plenty to get on with in the meantime!

In September we launched in John Lewis in the UK; we got to see our Briiv in a major retailer in person and introduce it to a new customer base. The following month we were featured in the Grand Designs magazine, and in November Briiv was released on Goop in the US!

Over the Christmas period we were busier than ever, and that’s not even accounting for everything our wholesalers and retail partners sold. Over 2022 as a whole, we saved 58,829kg of plastic from going to landfill; that’s almost 10 million plastic bags! We planted 4,854 trees, and even took the team out to do some of these ourselves.

Now we’re in the new year we’re focusing on developing Briiv further with app upgrades, new filters, and working with more partners around the world. It’s been a long journey to get here, and we couldn’t have done any of it without our team and the support of all our customers over the years. This is just the start of what we have planned for Briiv, so watch this space for everything that’s to come…